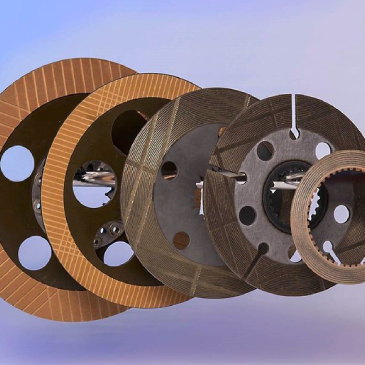

Wet Friction Plates

ProTec is a global producer and supplier of wet friction brake and transmission materials & parts for Industry, Mining, Agriculture, Construction, Transport and Motorsports. Our OE credentials are second to none and our service level is renowned. Scroll down to see more about our friction composites or to search our extensive catalog for the parts you need.

Sintered Bronze/Iron Plates

Sintered Bronze material consists of a high proportion of copper, as well as the carefully chosen types of graphite and silicate resulting in high wear resistance of the part even under high energy conditions. Sintered Iron has a higher proportion of iron material appropriate for the toughest applications, such as competition racing and freight rail.

The friction material is sprayed onto a steel core plate and then grooved in any number of patterns to achieve the optimal flow of oil across the friction face. Sintered Bronze/Iron materials are suitable for use in both ‘wet’ and ‘dry’ applications. For the Ultimate in wear-life and performance, consider TT137, our pressure-driven sintered.

Featured Material: TT131 Sintered Bronze Friction Material

Carbon Wet Friction Plates

Carbon fiber-reinforced silicon carbide materials thus combine the useful properties of carbon fiber-reinforced carbon (C/C) and polycrystalline silicon carbide ceramics.

Other advantages include much better braking response, higher fading stability, very good control, better directional stability and prevention of brake dust. High thermal stability, corrosion resistance and wear resistance ensure an exceptionally long brake disk life.

Featured Materials: TTC141 Carbon Friction Material

TTP127 Carbon Friction Paper

TTP128 Carbon Friction Paper

Paper Wet Friction Plates

Although produced by the paper making process, these materials are in fact elaborate composite cotton structures with a variety of reinforcing fibers including aramid, graphite and carbon.

Paper’s stable friction co-efficient and strong abrasion resistance and porosity make it an ideal material for wet wheel brakes and clutches, power transmissions and static brakes.

The material is blanked from a sheet, bonded to a steel core plate and then grooved in any number of patterns to achieve the optimal flow of oil across the friction face.

Featured Materials: TTP120 Advanced Friction Paper

TTP125 Advanced Friction Paper

Graphite Wet Friction Plates

Graphite friction materials in wet applications have a high percentage of carbonaceous components and are approximately 30% porous, providing:

- Extremely high energy dissipation capacity

- Outstanding thermal stability in high energy applications

- Stable coefficient of friction 0.11 dynamic and 0.14 static

- Good wear resistance

Featured Material: TTG149 Graphite Friction Material

Steel Plates

Steel is the primary mating surface used in wet brakes and clutches and can be used as the primary heat sink or the means to dissipate the energy into the ambient surroundings.

In a “wet” or oil-immersed application, oil molecules are trapped between the steel mating plate and the friction material. The surface roughness of the steel mating plate and the texture of the friction material combine on shear of the oil to deliver a co-efficient of friction of up to 0.15. Surface roughness is therefore critical to the application and has to be compatible with the opposing friction material.

Steel quality and hardness are application dependent but equally important. Usually a material such as CS 70 would be typical with a minimum hardness of Roc C 25. Further processes such as induction hardening and blackodising are used as required.