Understanding Sliding Friction and the Role of Low Friction Sliding Materials in Modern Engineering

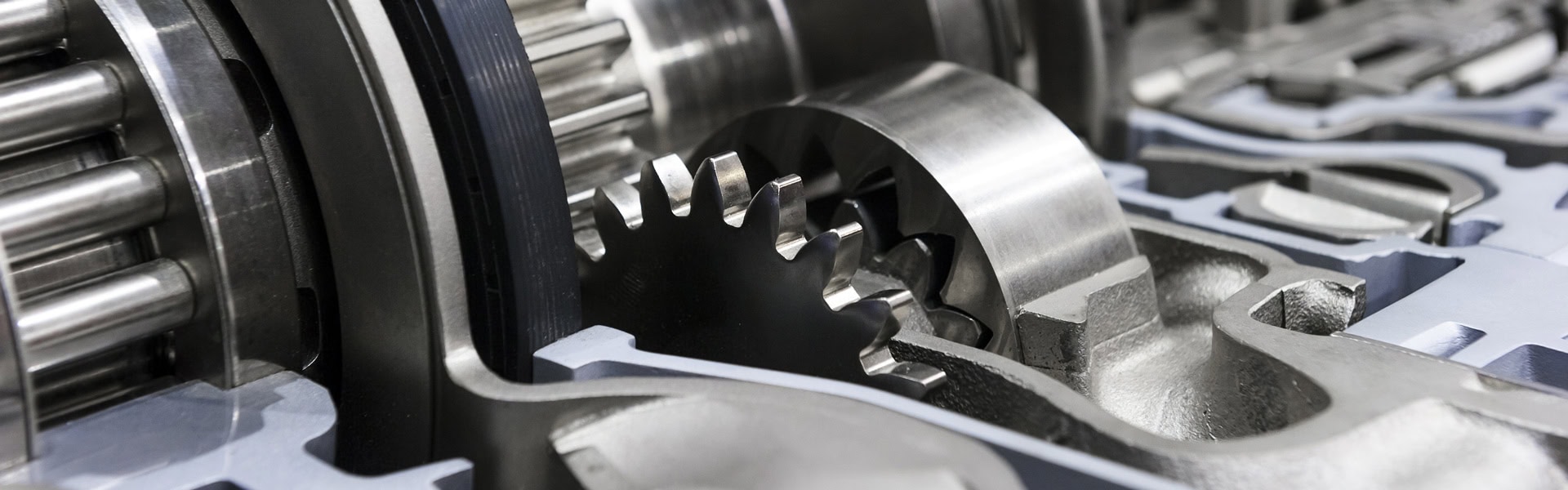

In mechanical and industrial systems, movement between surfaces is unavoidable. Whether it is linear motion, rotational contact, or oscillating movement, surfaces interacting under load generate resistance known as friction. Engineers rely on low friction sliding material solutions to manage this resistance, ensuring smooth motion, reduced wear, and consistent performance across a wide range of applications. Selecting the correct material is critical for maintaining efficiency and extending component life in demanding environments.

At the core of motion control is sliding friction, which occurs when two solid surfaces move against each other while remaining in contact. This form of friction directly impacts heat generation, energy efficiency, surface degradation, and system reliability. If sliding friction is not properly controlled, machinery can experience excessive wear, increased power consumption, and unplanned downtime. As equipment becomes more advanced and operates under higher loads and speeds, the importance of managing sliding friction continues to grow.

The physical process known as frictional sliding plays a major role in how materials behave under stress, pressure, and temperature variation. Engineers must understand how frictional sliding affects performance in real-world conditions, especially in applications involving continuous motion, repeated cycles, or harsh operating environments. At ProTec Friction Group, decades of material science expertise allow us to help manufacturers optimize sliding behavior through advanced material selection, formulation, and surface engineering.

What Is Sliding Friction

Sliding friction is the resistance encountered when one surface moves across another surface while both remain in contact. Unlike rolling friction, where movement occurs through rotation, sliding friction involves direct surface to surface interaction.

Key characteristics of sliding friction include:

- Continuous contact between surfaces

- Heat generation due to resistance

- Surface wear over time

- Dependence on material properties and surface condition

- Sensitivity to load, speed, and lubrication

Sliding friction exists in nearly every mechanical system, including guide rails, bearings, pistons, bushings, gears, and industrial machinery components.

Understanding Frictional Sliding at the Material Level

Frictional sliding is governed by complex interactions at the microscopic level. Even surfaces that appear smooth contain microscopic peaks and valleys. When two surfaces slide against each other, these irregularities interlock, deform, and generate resistance.

Several factors influence frictional sliding behavior:

- Material Composition

Different materials exhibit different frictional characteristics. Polymers, metals, ceramics, and composites each respond uniquely to sliding contact. - Surface Roughness

Rough surfaces generally produce higher friction, while smoother surfaces tend to slide more easily. - Contact Pressure

As pressure increases, frictional forces usually increase until material deformation or breakdown occurs. - Temperature

Higher temperatures can soften materials, alter surface chemistry, or reduce lubrication effectiveness. - Presence of Lubrication

Lubricants reduce direct surface contact, lowering friction and wear.

Understanding these variables helps engineers select materials that control frictional sliding under specific operating conditions.

Why Low Friction Sliding Material Is Critical

Low friction sliding materials are engineered to minimize resistance during surface movement. These materials play a crucial role in improving mechanical efficiency and system reliability.

Benefits of low friction sliding materials include:

- Reduced energy consumption

- Lower heat generation

- Minimized surface wear

- Longer component service life

- Improved precision and motion control

- Reduced maintenance and downtime

Industries that depend on continuous or repetitive motion rely heavily on low friction sliding materials to maintain productivity and safety.

Common Applications of Sliding Friction Control

Sliding friction is present in countless industrial and commercial applications. Controlling it effectively is essential for performance and durability.

Industrial Machinery

Guideways, sliders, cams, and actuators require controlled friction to ensure accurate movement and long service life.

Automotive and Transportation

Pistons, cylinder liners, transmission components, and suspension systems depend on low friction sliding behavior for efficiency.

Manufacturing Automation

Robotic arms, conveyors, and CNC machines rely on smooth sliding motion for precision and repeatability.

Construction and Heavy Equipment

Moving joints, hydraulic components, and wear plates experience high sliding friction under heavy loads.

Agriculture Equipment

Harvesters, tractors, and attachments depend on friction controlled materials to withstand dust, moisture, and continuous operation.

Materials Commonly Used as Low Friction Sliding Material

Engineers choose low friction materials based on load requirements, operating speed, environment, and desired lifespan. Several material categories are widely used.

Polymers and Engineered Plastics

Materials such as PTFE, UHMW polyethylene, nylon, and acetal provide excellent sliding properties with low friction and good wear resistance.

Metal Based Materials

Bronze alloys, aluminum alloys, and specialty steels are used where strength and heat resistance are required. These materials often rely on surface treatments or lubrication to reduce friction.

Composite Materials

Fiber reinforced composites combine strength with low friction characteristics, making them ideal for demanding industrial applications.

Carbon and Graphite Materials

Carbon based materials offer natural lubricity and perform well under high temperatures and loads.

Ceramic Materials

Advanced ceramics provide low friction and high wear resistance in extreme environments.

Managing Sliding Friction Through Material Pairing

Sliding performance depends not only on the sliding material itself but also on the mating surface. Selecting compatible material pairs is essential to controlling friction and wear.

Effective material pairing helps achieve:

- Stable friction levels

- Reduced surface damage

- Lower heat buildup

- Predictable wear patterns

Examples of effective material pairings include polymer against steel, graphite infused bronze against hardened metal, and coated metal against composite surfaces. ProTec engineers evaluate both sides of the sliding interface to ensure optimal performance.

The Role of Surface Engineering in Frictional Sliding

Surface engineering plays a critical role in managing frictional sliding without changing the base material. Treatments and coatings modify surface properties to improve sliding behavior.

Common surface engineering approaches include:

- Polishing and surface finishing

- Hardening treatments

- Application of low friction coatings

- Texturing for lubrication retention

- Chemical surface modification

Low friction coatings such as PTFE based layers, molybdenum disulfide, ceramic coatings, and carbon based coatings help reduce resistance and protect surfaces from wear.

Challenges Associated With Sliding Friction

If sliding friction is not properly managed, several issues may arise:

- Excessive wear and abrasion

- Heat induced deformation

- Loss of dimensional accuracy

- Increased power consumption

- Noise and vibration

- Reduced equipment lifespan

These challenges are magnified in high load, high speed, or contaminated environments, making material selection and engineering critical.

How ProTec Approaches Sliding Friction Optimization

ProTec Friction Group applies decades of material science and engineering expertise to solve sliding friction challenges across industries.

Our approach includes:

Material Evaluation

We assess operating conditions such as load, speed, temperature, and environment to identify suitable low friction materials.

Custom Material Development

Our engineers develop proprietary material formulations tailored to specific sliding friction requirements.

Surface Interaction Analysis

We evaluate how materials interact at the sliding interface to minimize wear and instability.

Testing and Validation

Materials undergo laboratory and application testing to ensure consistent performance under real world conditions.

Lifecycle Cost Optimization

We focus on reducing total cost of ownership by extending service life and minimizing maintenance needs.

Industries Served by ProTec Sliding Material Solutions

ProTec supports a wide range of industries where frictional sliding control is essential.

- Agriculture

- Construction and heavy equipment

- Mining

- Marine

- Oil and gas

- Manufacturing and automation

- Transportation and logistics

Each industry presents unique challenges, and ProTec develops solutions that address specific operational demands.

Balancing Sliding Friction With Structural Performance

While reducing friction is important, materials must also maintain strength, stability, and durability. A successful low friction sliding material must balance:

- Friction reduction

- Load carrying capacity

- Wear resistance

- Thermal stability

- Environmental resistance

ProTec engineers ensure that friction reduction never compromises structural integrity or safety.

Conclusion

Understanding sliding friction and the mechanics of frictional sliding is essential for designing efficient, durable mechanical systems. Selecting the right low friction sliding material allows manufacturers to reduce wear, improve efficiency, and extend equipment lifespan across a wide range of applications.

With decades of experience and advanced material science capabilities, ProTec Friction Group delivers engineered solutions that help customers control friction precisely where it matters most. Whether optimizing sliding components, developing custom materials, or improving surface interactions, ProTec is committed to delivering performance driven, reliable solutions.

Contact ProTec today to discuss how our low friction sliding material expertise can enhance your equipment performance and reduce operational costs.