High Coefficient of Friction Materials and Their Role in Industrial Performance

Comments Off on High Coefficient of Friction Materials and Their Role in Industrial PerformanceHigh Coefficient of Friction Materials and Their Role in Industrial Performance

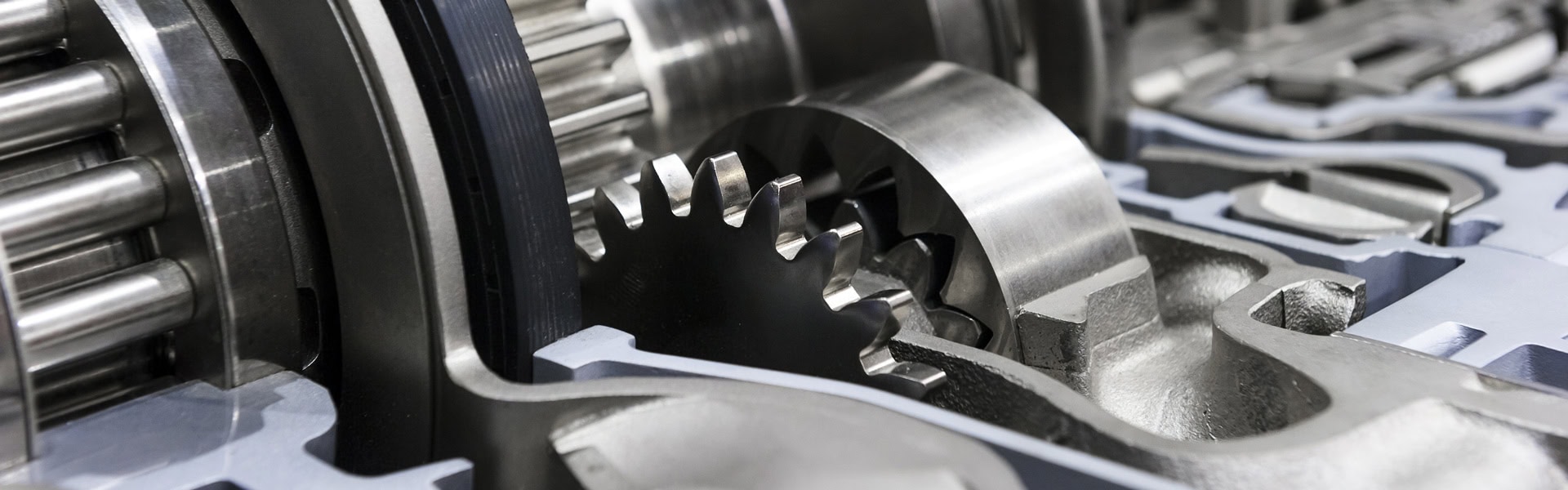

Engineering systems that rely on controlled stopping, load holding, or torque transmission depend heavily on friction behavior. In these systems, the use of High Coefficient of Friction Materials is not optional but fundamental to safety, efficiency, and reliability. Braking systems, clutch assemblies, and industrial holding mechanisms all rely on materials that can generate sufficient friction under pressure while remaining stable across temperature and duty cycles.

Design teams often search for the Material With Highest Coefficient of Friction, assuming that higher numerical values automatically translate to better performance. In reality, friction behavior is far more complex. A material that performs well in laboratory testing may degrade rapidly when exposed to heat, contamination, or repeated engagement. This is why published Coefficient of Friction Values for Different Materials must be evaluated alongside real world operating conditions.

At ProTec Friction Group, friction is treated as an engineered outcome rather than a static number. Since 1988, we have worked with OEMs, equipment manufacturers, and rebuilders to develop friction materials that deliver consistent, repeatable performance under demanding industrial conditions rather than short term peak values that decline in service.

What a High Coefficient of Friction Really Means

A high coefficient of friction indicates greater resistance to motion between two contacting surfaces. However, this value is influenced by multiple variables that must be considered together.

Key factors affecting friction coefficient include:

- Surface roughness and texture

- Material composition and bonding agents

- Contact pressure and load distribution

- Sliding speed and engagement frequency

- Operating temperature

- Presence of contaminants or lubrication

Because of these variables, friction coefficients are best understood as performance ranges rather than fixed values.

Static vs Dynamic Friction in High Friction Applications

In most industrial systems, friction is not a single event but a continuous process. It is important to distinguish between static and dynamic friction.

Static friction governs initial engagement, such as when a clutch begins to transfer torque. Dynamic friction controls behavior once motion is underway, such as during continuous braking or sustained clutch slip.

For many applications, stable dynamic friction is more important than peak static friction. A material that maintains consistent friction during operation provides better control, reduced vibration, and lower wear than a material that spikes briefly and then fades.

Categories of High Coefficient of Friction Materials

High friction materials are typically grouped based on composition and performance characteristics.

Organic Composite Materials

- Smooth engagement behavior

- Moderate to high friction levels

- Common in light to medium duty applications

Semi Metallic Friction Materials

- Higher friction and improved heat dissipation

- Better performance under heavier loads

- Widely used in industrial and commercial braking

Fully Metallic Materials

- Very high friction capability

- Excellent thermal stability

- Suitable for extreme duty environments

Ceramic and Mineral Reinforced Materials

- Stable friction at elevated temperatures

- Reduced fade and glazing

- Increasingly used in high energy braking systems

Advanced Fiber Composites

- High strength and consistent friction

- Excellent wear resistance

- Designed for long service life

ProTec develops proprietary blends across these categories to match specific application requirements.

The Importance of Mating Surfaces

Friction materials do not operate in isolation. Their performance is directly affected by the mating surface.

Critical mating surface characteristics include:

- Material hardness and alloy composition

- Surface finish and roughness

- Heat absorption and dissipation

- Resistance to scoring and deformation

A friction material with excellent properties can underperform or cause excessive wear if paired with an incompatible surface. ProTec evaluates friction material and mating surface as a complete system to ensure stability and longevity.

Interpreting Coefficient of Friction Values for Different Materials

Published friction coefficient tables are useful reference tools, but they do not tell the full story.

Limitations of published values include:

- Testing under ideal laboratory conditions

- Absence of thermal cycling effects

- No exposure to contamination or vibration

- Short duration measurement windows

Real world applications often produce friction behavior that differs significantly from published data. This is why ProTec emphasizes application specific testing rather than relying solely on standardized values.

Why the Highest Friction Is Not Always the Best Choice

In heavy duty applications such as mining, rail, marine, and off highway equipment, extremely high friction can introduce new problems.

Potential issues include:

- Excessive heat generation

- Accelerated wear of mating components

- Noise and vibration

- Structural breakdown under sustained load

In many cases, a slightly lower but more stable friction material delivers superior overall performance and lower lifecycle cost.

Engineering for Stability Instead of Peak Friction

ProTec’s formulation philosophy focuses on friction consistency rather than maximum friction numbers.

Our engineers design materials to:

- Maintain stable friction across temperature ranges

- Resist fade and glazing

- Provide predictable wear patterns

- Support long service intervals

- Reduce system overengineering

This approach allows equipment designers to optimize system size, improve efficiency, and reduce maintenance requirements.

Industries That Rely on High Friction Materials

High coefficient of friction materials play a critical role across many sectors.

Industries served include:

- Agriculture and harvesting equipment

- Construction and earthmoving machinery

- Mining and heavy haul operations

- Rail and transit systems

- Marine propulsion and deck machinery

- Industrial manufacturing and material handling

Each industry presents unique environmental and mechanical challenges that require tailored friction solutions.

Sustainability and Modern Friction Material Development

Environmental responsibility is becoming increasingly important in friction material design. Traditional high friction materials often relied on components that are now restricted or undesirable.

ProTec actively develops materials that:

- Reduce particulate emissions

- Extend component service life

- Lower overall material consumption

- Support cleaner industrial operation

Sustainable performance is now a core design requirement rather than an afterthought.

Testing and Validation at ProTec

Reliable friction performance must be proven, not assumed.

ProTec validates materials through:

- Laboratory friction and wear testing

- Thermal cycling evaluation

- Simulated duty cycle testing

- Field performance validation

Only materials that demonstrate repeatable performance under realistic conditions advance to production.

Conclusion

High coefficient of friction materials are essential for braking, clutching, and load holding systems, but their value lies in controlled and stable performance rather than peak numbers alone. The Material With Highest Coefficient of Friction on paper is rarely the best solution in practice. Understanding Coefficient of Friction Values for Different Materials requires context, system level analysis, and real world validation.

ProTec Friction Group delivers engineered friction solutions designed to perform consistently under the most demanding industrial conditions. By focusing on stability, durability, and application specific performance, we help customers reduce risk, extend service life, and improve overall system reliability. Contact ProTec today to discuss how our friction expertise can support your next application.

Understanding Transmission Friction Modifiers and Their Role in Drivetrain Performance

Comments Off on Understanding Transmission Friction Modifiers and Their Role in Drivetrain PerformanceUnderstanding Transmission Friction Modifiers and Their Role in Drivetrain Performance

Modern transmissions operate under extreme mechanical and thermal stress. From heavy duty industrial gearboxes to commercial vehicle drivetrains, consistent friction behavior is critical for smooth shifting, torque transfer, and component longevity. A Transmission Friction Modifier is engineered to fine tune friction characteristics inside the transmission system, ensuring controlled engagement between moving parts while minimizing wear and heat generation. These additives and material technologies help maintain stability under varying loads, speeds, and temperatures.

Selecting the Best Transmission Friction Modifier requires understanding how friction behaves inside clutch packs, synchronizers, gears, and bearings. If friction is too high, components wear prematurely and shifting becomes harsh. If friction is too low, slippage occurs, leading to power loss, overheating, and long term damage. Manufacturers, rebuilders, and fleet operators rely on precisely engineered friction modifiers to maintain balance across these competing demands.

Many buyers encounter aftermarket options marketed under names such as Friction Modifier Advance Auto Parts, but professional grade friction solutions require far deeper engineering than generic additives. At ProTec Friction Group, we apply decades of friction material science expertise to understand how modifiers interact with base oils, clutch materials, and mating surfaces. This ensures performance improvements that are measurable, repeatable, and durable under real world operating conditions.

What Is a Transmission Friction Modifier

A transmission friction modifier is a chemical or material based solution designed to alter the frictional properties of contact surfaces inside a transmission. These modifiers are commonly blended into transmission fluids or engineered directly into friction materials used in clutch packs and bands. Their primary function is to regulate the coefficient of friction to achieve smooth engagement, controlled torque transfer, and reduced wear.

Transmission friction modifiers work by forming a microscopic boundary layer between interacting surfaces. This layer reduces direct metal to metal contact while maintaining enough friction for proper clutch engagement. The result is smoother shifting, reduced vibration, improved heat management, and longer component life.

Why Friction Control Is Critical in Transmissions

Transmissions depend on controlled friction more than almost any other mechanical system. Every shift event requires precise friction behavior to synchronize rotating components without shock or slip. Poor friction control leads to several common issues including harsh shifting, shudder during engagement, delayed response, overheating, and accelerated wear of clutch packs and synchronizers.

Friction modifiers help stabilize friction across a wide range of operating conditions. As temperature rises and fluid viscosity changes, friction modifiers ensure that performance remains predictable. This stability is especially important in heavy duty commercial vehicles, industrial equipment, agricultural machinery, marine systems, and off highway applications where transmissions experience sustained high loads.

How Transmission Friction Modifiers Work

Friction modifiers operate at the surface level. When added to transmission fluid or integrated into friction materials, they attach to metal and composite surfaces, smoothing microscopic asperities that cause erratic friction behavior.

Key functions include reducing stick slip behavior during clutch engagement, controlling torque capacity under load, minimizing heat generation, and protecting surfaces from abrasion and chemical degradation. Advanced friction modifiers are designed to remain stable under high temperatures and resist breakdown over extended service intervals.

Characteristics of the Best Transmission Friction Modifier

Not all friction modifiers deliver the same results. The best solutions are engineered to meet specific transmission designs and operating conditions.

A high quality transmission friction modifier demonstrates friction stability across temperature ranges, compatibility with transmission fluids and seals, resistance to oxidation and shear breakdown, and predictable interaction with clutch materials. It must support smooth engagement without sacrificing torque capacity or durability.

Professional grade friction modifiers are validated through laboratory testing and real world performance trials rather than marketing claims. This is where engineering driven companies separate from retail focused solutions.

Transmission Systems That Benefit From Friction Modifiers

Automatic transmissions rely heavily on friction modifiers to manage clutch engagement and shift quality. Manual transmissions benefit through smoother synchronizer operation and reduced gear wear. Continuously variable transmissions require extremely precise friction control to prevent belt or chain slippage while maintaining efficiency.

Industrial gearboxes, marine transmissions, agricultural drivetrains, and construction equipment also rely on friction modifiers to handle heavy loads, frequent cycling, and harsh environments. In these systems, friction stability directly impacts uptime, safety, and operating costs.

Friction Modifiers Versus Generic Aftermarket Additives

Many aftermarket products are marketed broadly as friction modifiers, including those sold under consumer retail brands such as Friction Modifier Advance Auto Parts. While these products may offer short term improvements for light duty applications, they often lack the formulation depth required for demanding industrial or commercial use.

Generic additives may not be optimized for specific clutch materials, fluid chemistries, or operating temperatures. In some cases, improper additives can cause excessive slippage, seal compatibility issues, or accelerated degradation of transmission components.

Engineered friction solutions developed by specialists like ProTec are formulated with a deep understanding of material interactions and long term performance requirements.

The Role of Friction Modifiers in Heat Management

Heat is one of the primary enemies of transmission systems. Excessive friction generates heat that degrades fluids, weakens materials, and accelerates wear. Transmission friction modifiers play a vital role in controlling heat by reducing unnecessary friction while maintaining functional engagement.

By stabilizing friction behavior, modifiers prevent energy loss during shifting and torque transfer. This results in lower operating temperatures, improved fluid life, and reduced thermal stress on internal components.

Interaction With Transmission Fluids

Transmission friction modifiers must be compatible with the base fluid chemistry. Modern transmission fluids are complex blends of base oils, detergents, dispersants, anti wear agents, and viscosity modifiers.

A well designed friction modifier integrates seamlessly into this system, enhancing performance without disrupting fluid balance. Poorly formulated additives can interfere with lubrication properties, reduce film strength, or accelerate oxidation. ProTec evaluates friction modifiers as part of the complete fluid and material system rather than as isolated components.

Friction Modifiers and Clutch Material Compatibility

Transmission clutches are manufactured from a variety of materials including paper based composites, carbon fiber blends, sintered metals, and advanced fiber composites. Each material responds differently to friction modifiers.

The best transmission friction modifier is engineered to complement the clutch material rather than overpower it. Proper compatibility ensures smooth engagement, minimal wear, and stable friction throughout the service life of the transmission.

ProTec’s Engineering Approach to Transmission Friction Control

At ProTec Friction Group, friction control is approached as a system level challenge rather than a single component solution. Our engineers evaluate operating conditions such as torque loads, duty cycles, temperature profiles, fluid chemistry, and material interactions.

Our experience in brake and clutch materials gives us a unique perspective on friction behavior across a wide range of applications.

Industrial and Commercial Applications Served

ProTec friction solutions support industries including commercial transportation, agriculture, construction, mining, marine, oilfield operations, manufacturing automation, and heavy industrial processing. In each case, friction modifiers help extend transmission life, improve efficiency, and reduce downtime.

Whether the application involves continuous operation, frequent shifting, high torque loads, or extreme environmental exposure, ProTec delivers solutions engineered for performance and reliability.

Long Term Benefits of Proper Friction Modification

When the correct transmission friction modifier is used, organizations benefit from smoother shifting, reduced vibration, improved power transfer, lower operating temperatures, extended service intervals, and reduced total cost of ownership.

These benefits compound over time, improving equipment availability and reducing maintenance expenses. Proper friction control also enhances operator comfort and system safety.

Conclusion

Transmission performance depends on precise friction control. A properly engineered Transmission Friction Modifier ensures smooth engagement, stable torque transfer, and long term durability across a wide range of operating conditions. Selecting the Best Transmission Friction Modifier requires more than choosing a retail additive such as Friction Modifier Advance Auto Parts offerings. It requires an understanding of material science, fluid chemistry, and system level interactions.

ProTec Friction Group applies decades of engineering expertise to develop friction solutions that meet the demands of modern transmission systems. Our focus on precision, durability, and performance helps customers optimize drivetrain efficiency and reduce lifecycle costs.

Understanding Sliding Friction and the Role of Low Friction Sliding Materials in Modern Engineering

Comments Off on Understanding Sliding Friction and the Role of Low Friction Sliding Materials in Modern EngineeringUnderstanding Sliding Friction and the Role of Low Friction Sliding Materials in Modern Engineering

In mechanical and industrial systems, movement between surfaces is unavoidable. Whether it is linear motion, rotational contact, or oscillating movement, surfaces interacting under load generate resistance known as friction. Engineers rely on low friction sliding material solutions to manage this resistance, ensuring smooth motion, reduced wear, and consistent performance across a wide range of applications. Selecting the correct material is critical for maintaining efficiency and extending component life in demanding environments.

At the core of motion control is sliding friction, which occurs when two solid surfaces move against each other while remaining in contact. This form of friction directly impacts heat generation, energy efficiency, surface degradation, and system reliability. If sliding friction is not properly controlled, machinery can experience excessive wear, increased power consumption, and unplanned downtime. As equipment becomes more advanced and operates under higher loads and speeds, the importance of managing sliding friction continues to grow.

The physical process known as frictional sliding plays a major role in how materials behave under stress, pressure, and temperature variation. Engineers must understand how frictional sliding affects performance in real-world conditions, especially in applications involving continuous motion, repeated cycles, or harsh operating environments. At ProTec Friction Group, decades of material science expertise allow us to help manufacturers optimize sliding behavior through advanced material selection, formulation, and surface engineering.

What Is Sliding Friction

Sliding friction is the resistance encountered when one surface moves across another surface while both remain in contact. Unlike rolling friction, where movement occurs through rotation, sliding friction involves direct surface to surface interaction.

Key characteristics of sliding friction include:

- Continuous contact between surfaces

- Heat generation due to resistance

- Surface wear over time

- Dependence on material properties and surface condition

- Sensitivity to load, speed, and lubrication

Sliding friction exists in nearly every mechanical system, including guide rails, bearings, pistons, bushings, gears, and industrial machinery components.

Understanding Frictional Sliding at the Material Level

Frictional sliding is governed by complex interactions at the microscopic level. Even surfaces that appear smooth contain microscopic peaks and valleys. When two surfaces slide against each other, these irregularities interlock, deform, and generate resistance.

Several factors influence frictional sliding behavior:

- Material Composition

Different materials exhibit different frictional characteristics. Polymers, metals, ceramics, and composites each respond uniquely to sliding contact. - Surface Roughness

Rough surfaces generally produce higher friction, while smoother surfaces tend to slide more easily. - Contact Pressure

As pressure increases, frictional forces usually increase until material deformation or breakdown occurs. - Temperature

Higher temperatures can soften materials, alter surface chemistry, or reduce lubrication effectiveness. - Presence of Lubrication

Lubricants reduce direct surface contact, lowering friction and wear.

Understanding these variables helps engineers select materials that control frictional sliding under specific operating conditions.

Why Low Friction Sliding Material Is Critical

Low friction sliding materials are engineered to minimize resistance during surface movement. These materials play a crucial role in improving mechanical efficiency and system reliability.

Benefits of low friction sliding materials include:

- Reduced energy consumption

- Lower heat generation

- Minimized surface wear

- Longer component service life

- Improved precision and motion control

- Reduced maintenance and downtime

Industries that depend on continuous or repetitive motion rely heavily on low friction sliding materials to maintain productivity and safety.

Common Applications of Sliding Friction Control

Sliding friction is present in countless industrial and commercial applications. Controlling it effectively is essential for performance and durability.

Industrial Machinery

Guideways, sliders, cams, and actuators require controlled friction to ensure accurate movement and long service life.

Automotive and Transportation

Pistons, cylinder liners, transmission components, and suspension systems depend on low friction sliding behavior for efficiency.

Manufacturing Automation

Robotic arms, conveyors, and CNC machines rely on smooth sliding motion for precision and repeatability.

Construction and Heavy Equipment

Moving joints, hydraulic components, and wear plates experience high sliding friction under heavy loads.

Agriculture Equipment

Harvesters, tractors, and attachments depend on friction controlled materials to withstand dust, moisture, and continuous operation.

Materials Commonly Used as Low Friction Sliding Material

Engineers choose low friction materials based on load requirements, operating speed, environment, and desired lifespan. Several material categories are widely used.

Polymers and Engineered Plastics

Materials such as PTFE, UHMW polyethylene, nylon, and acetal provide excellent sliding properties with low friction and good wear resistance.

Metal Based Materials

Bronze alloys, aluminum alloys, and specialty steels are used where strength and heat resistance are required. These materials often rely on surface treatments or lubrication to reduce friction.

Composite Materials

Fiber reinforced composites combine strength with low friction characteristics, making them ideal for demanding industrial applications.

Carbon and Graphite Materials

Carbon based materials offer natural lubricity and perform well under high temperatures and loads.

Ceramic Materials

Advanced ceramics provide low friction and high wear resistance in extreme environments.

Managing Sliding Friction Through Material Pairing

Sliding performance depends not only on the sliding material itself but also on the mating surface. Selecting compatible material pairs is essential to controlling friction and wear.

Effective material pairing helps achieve:

- Stable friction levels

- Reduced surface damage

- Lower heat buildup

- Predictable wear patterns

Examples of effective material pairings include polymer against steel, graphite infused bronze against hardened metal, and coated metal against composite surfaces. ProTec engineers evaluate both sides of the sliding interface to ensure optimal performance.

The Role of Surface Engineering in Frictional Sliding

Surface engineering plays a critical role in managing frictional sliding without changing the base material. Treatments and coatings modify surface properties to improve sliding behavior.

Common surface engineering approaches include:

- Polishing and surface finishing

- Hardening treatments

- Application of low friction coatings

- Texturing for lubrication retention

- Chemical surface modification

Low friction coatings such as PTFE based layers, molybdenum disulfide, ceramic coatings, and carbon based coatings help reduce resistance and protect surfaces from wear.

Challenges Associated With Sliding Friction

If sliding friction is not properly managed, several issues may arise:

- Excessive wear and abrasion

- Heat induced deformation

- Loss of dimensional accuracy

- Increased power consumption

- Noise and vibration

- Reduced equipment lifespan

These challenges are magnified in high load, high speed, or contaminated environments, making material selection and engineering critical.

How ProTec Approaches Sliding Friction Optimization

ProTec Friction Group applies decades of material science and engineering expertise to solve sliding friction challenges across industries.

Our approach includes:

Material Evaluation

We assess operating conditions such as load, speed, temperature, and environment to identify suitable low friction materials.

Custom Material Development

Our engineers develop proprietary material formulations tailored to specific sliding friction requirements.

Surface Interaction Analysis

We evaluate how materials interact at the sliding interface to minimize wear and instability.

Testing and Validation

Materials undergo laboratory and application testing to ensure consistent performance under real world conditions.

Lifecycle Cost Optimization

We focus on reducing total cost of ownership by extending service life and minimizing maintenance needs.

Industries Served by ProTec Sliding Material Solutions

ProTec supports a wide range of industries where frictional sliding control is essential.

- Agriculture

- Construction and heavy equipment

- Mining

- Marine

- Oil and gas

- Manufacturing and automation

- Transportation and logistics

Each industry presents unique challenges, and ProTec develops solutions that address specific operational demands.

Balancing Sliding Friction With Structural Performance

While reducing friction is important, materials must also maintain strength, stability, and durability. A successful low friction sliding material must balance:

- Friction reduction

- Load carrying capacity

- Wear resistance

- Thermal stability

- Environmental resistance

ProTec engineers ensure that friction reduction never compromises structural integrity or safety.

Conclusion

Understanding sliding friction and the mechanics of frictional sliding is essential for designing efficient, durable mechanical systems. Selecting the right low friction sliding material allows manufacturers to reduce wear, improve efficiency, and extend equipment lifespan across a wide range of applications.

With decades of experience and advanced material science capabilities, ProTec Friction Group delivers engineered solutions that help customers control friction precisely where it matters most. Whether optimizing sliding components, developing custom materials, or improving surface interactions, ProTec is committed to delivering performance driven, reliable solutions.

Contact ProTec today to discuss how our low friction sliding material expertise can enhance your equipment performance and reduce operational costs.