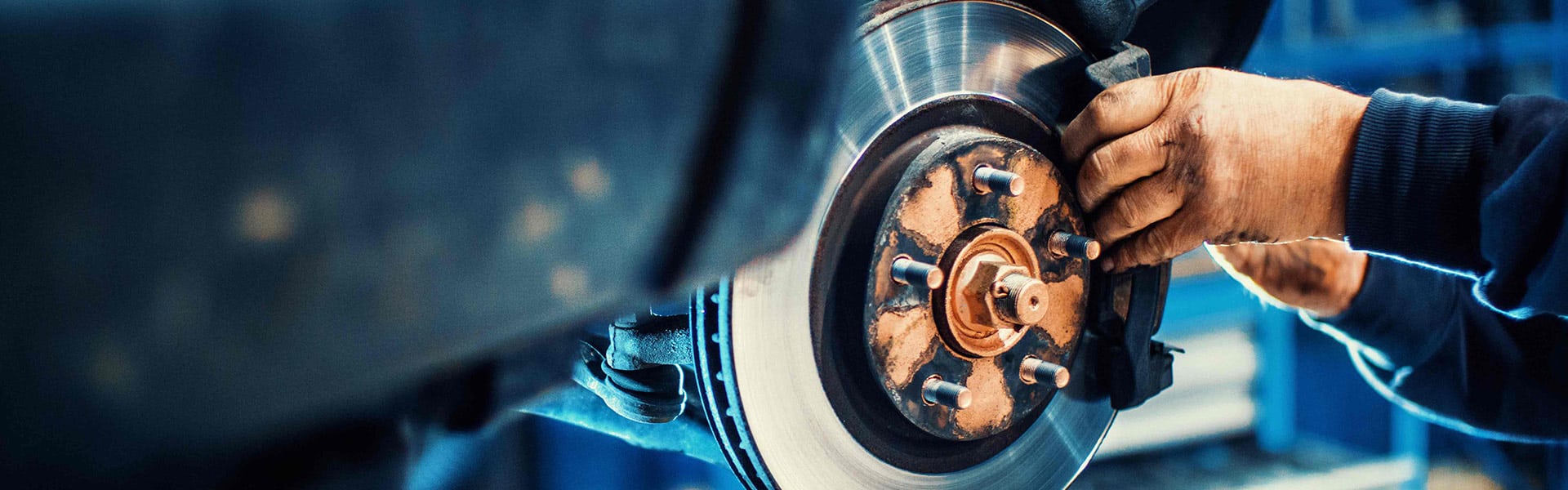

A Deep Look at Materials With High Friction Coefficients for Advanced Brake and Clutch Systems

The performance of any brake or clutch system depends heavily on the type of materials selected for the friction surfaces. In industries where reliability, torque capacity, and heat stability matter, engineers rely on materials with high friction coefficients to ensure predictable and consistent performance. These specialized compounds are specifically engineered to maintain their friction level under heavy loads, high temperatures, and challenging environmental conditions.

Selecting the right materials with high coefficient of friction is essential for equipment operating in demanding applications such as off highway machinery, agricultural equipment, heavy trucks, marine systems, mining vehicles, oilfield tools, and industrial production lines. Choosing the wrong material can lead to slippage, unpredictable braking response, excessive heat generation, or premature wear. That is why manufacturers often depend on engineered compounds developed through extensive testing and precise formulation.

At ProTec Friction Group, our engineering team develops and supplies high coefficient of friction materials designed to deliver optimal performance in high energy braking and clutching environments. Our advanced formulations are the result of decades of research, real world testing, and continuous improvement. Since 1988, we have partnered with OEMs, rebuilders, and equipment dealers to supply friction materials tailored to meet the specific torque, heat, and operational demands of their systems.

What Makes a Material High Friction

A material qualifies as high friction when it consistently exhibits elevated friction levels during both initial engagement and continuous sliding. The friction coefficient is influenced by its composition, surface texture, temperature behavior, and interaction with the mating surface.

High friction materials often include:

- Reinforced fibers

- Metallic content

- Ceramic or mineral particles

- High temperature resins

- Specialty binders

- Carbon or graphite structures

These elements are blended to produce a stable friction curve across various pressures, speeds, and temperatures.

Why Industries Rely on Materials With High Friction Coefficients

For many industrial applications, high friction is not a convenience. It is a requirement for operational safety and performance. When heavy machinery needs to stop quickly or transmit high levels of torque reliably, only certain friction materials meet the standard.

- Better Braking Efficiency

A high coefficient of friction reduces stopping distance and improves response time, essential for safety in large mobile machinery or fast moving industrial equipment. - Higher Torque Capacity

Clutch systems need adequate friction to transfer power efficiently. High friction materials prevent slippage, improve torque handling, and extend component life. - Superior Heat Resistance

When friction increases, heat follows. High friction materials must be engineered to handle the thermal load without glazing, fading, or breaking down. - Enhanced Control and Stability

Operators rely on predictable friction behavior. Materials engineered for high friction maintain consistent feel and performance even in changing environments.

Key Characteristics of High Coefficient of Friction Materials

Not all high friction materials perform equally. The best formulations exhibit specific traits that contribute to longevity and reliability.

- Temperature Stability

A high friction material must maintain consistent friction at elevated temperatures. If not, the system can experience fade, a sudden drop in friction that reduces control. - Structural Integrity

Under high loads, friction materials must retain shape, grip, and strength. Reinforcement fibers and metallic content improve resistance to compression and wear. - Predictable Performance Curve

Engineers require friction curves that remain stable across different speeds and pressures. The best materials behave consistently regardless of variations in operation. - Fade and Glazing Resistance

Some materials lose friction when overheated. High friction materials incorporate heat resistant resins and additives that minimize glaze formation. - Compatibility With Mating Surfaces

A friction material must work in harmony with the disc, drum, or rotor surface. Poor compatibility increases wear or reduces effective friction.

Common Materials Used to Achieve High Friction Performance

Friction engineers choose materials based on the application’s load requirements, speed profile, environmental exposure, and durability expectations. Below are categories of materials known for delivering high friction characteristics.

1. Semi Metallic Composites

These materials use metallic particles mixed with synthetic fibers and resins. They provide:

- Excellent heat dissipation

- Strong friction levels

- High durability

- Stability during continuous operation

Semi metallic materials are common in industrial braking systems and medium to heavy duty commercial vehicles.

2. Fully Metallic Friction Materials

Made entirely from metal powders and fibers, these materials support extreme loads and heat. They are ideal for:

- Railroad braking

- Mining equipment

- Oilfield machinery

- Marine propulsion systems

Fully metallic options offer outstanding friction and durability but require compatible mating surfaces.

3. Ceramic and Mineral Enhanced Formulations

Ceramic particles provide exceptional heat stability, making them suitable for high speed or high energy environments. Their advantages include:

- Low wear debris

- Smooth friction curve

- High temperature endurance

Ceramic enhanced materials are preferred in applications that demand clean, stable performance.

4. Advanced Fiber Composites

Aramid, carbon, and glass fibers are used to strengthen friction materials while improving heat stability and wear resistance. Many high friction materials rely on advanced fiber reinforcement to maintain shape under stress.

5. Carbon Graphitic Materials

These blends offer strong friction performance while improving cooling and reducing wear. Carbon based materials are commonly used in performance braking systems and specialty industrial machinery.

How Mating Surfaces Impact High Friction Performance

The friction material works together with the mating surface to create the stopping or torque transferring force. Materials with high friction coefficients perform only as well as the surface they contact.

Common mating surfaces include:

- High strength steel plates

- Cast iron rotors

- Alloyed metals

- Hardened steels

- Composite discs

Engineers must evaluate:

- Roughness

- Heat conductivity

- Hardness

- Compatibility with friction compounds

ProTec specializes in pairing friction materials with the correct mating surfaces to optimize performance and service life.

Industrial Applications That Require High Coefficient of Friction Materials

Different industries rely on high friction materials for critical operational safety and performance.

Agriculture

Heavy equipment such as harvesters, tractors, and balers depend on high friction clutches and brakes for reliable power transfer and controlled stopping.

Construction

Loaders, excavators, graders, and cranes use high friction materials to handle steep gradients, heavy payloads, and constant braking cycles.

Off Highway Transport

Vehicles operating in rugged terrain require reliable braking under dust, moisture, and continuous load stress.

Rail and Transit

Rail braking systems require stable, high friction behavior under continuous, high speed conditions.

Marine

Marine winches, propulsion systems, and deck machinery benefit from high friction materials that withstand saltwater environments and heavy stress cycles.

Manufacturing and Assembly Lines

Precision control is essential for conveyors, press machines, and automated production systems, making high friction materials indispensable.

Engineering the Ideal High Friction Material

Developing high coefficient of friction materials involves a combination of chemistry, mechanical science, and real world testing. ProTec Friction Group follows a disciplined engineering process to ensure each formula meets the performance demands of the target application.

1. Material Selection

We evaluate fibers, metals, ceramics, resins, and binders based on thermal stability, friction behavior, and structural integrity.

2. Experimental Formulation

Multiple recipes are created and adjusted to achieve the desired friction curve and durability.

3. Laboratory Testing

Materials undergo testing for:

- Friction coefficient

- Wear rate

- Heat fade resistance

- Pressure sensitivity

- Contaminant exposure

4. Field Simulation

We simulate real operating conditions to observe friction behavior under load, speed, and temperature changes.

5. Performance Verification

Our team validates friction consistency, structural toughness, and compatibility with mating surfaces to ensure final success.

How High Friction Materials Reduce Lifecycle Costs

Manufacturers often assume that high friction materials increase cost, but in reality they often reduce total lifecycle expenses.

Longer Service Life

High friction materials last longer due to stronger reinforcement and improved heat resistance.

Lower Maintenance

Systems require fewer adjustments and less downtime when friction behavior remains consistent.

Better Efficiency

Efficient torque transfer improves operational output and reduces energy waste.

Fewer Failures

Stable friction reduces slippage, glazing, and overheating, preventing costly breakdowns.

When friction materials are engineered correctly, they not only improve performance but also drive long term savings.

Why ProTec Friction Group Leads in High Friction Material Innovation

For more than three decades, ProTec has been a recognized leader in the friction materials industry. What sets us apart is our ability to deliver tailored solutions, not one size fits all products.

We offer:

- Custom friction formulations

- Rapid development cycles

- Extensive real world testing

- Mating surface optimization

- High temperature friction materials

- Environmentally conscious formulations

- Support for OEMs, rebuilders, and specialty equipment manufacturers

Our partnerships are built on transparency, innovation, and long term commitment.

Conclusion

Selecting the right materials with high friction coefficients is essential for achieving reliable braking performance, strong torque transmission, and consistent operational control. Industries that rely on heavy machinery, high speed systems, or continuous duty cycles depend on materials with high coefficient of friction to ensure safety, durability, and efficiency. As demand for stronger and more sustainable solutions increases, the need for high coefficient of friction materials continues to grow across all industrial sectors.

ProTec Friction Group remains committed to advancing material science, improving friction stability, and delivering custom solutions that address real world engineering challenges. Whether you require a specialized high friction material, a custom formulation, or expert guidance on optimizing brake and clutch systems, our team is ready to assist.

Contact ProTec today to explore how our advanced friction materials can enhance your system’s performance and reduce operational costs.