Thermotech 120

TTP120 has an enhanced structure designed to provide superior energy capability, good engagement characteristic, low wear and long service life.

- Low ratio of static to dynamic coefficient of friction for enhanced engagement characteristics

- Smooth engagement

- Excellent energy capability

- Good wear resistance

TYPICAL APPLICATIONS Wheel Brakes, Transmissions, Power Shift and Power Take-Off Transmissions

MATING MATERIAL Steel, Cast Steel, Grey Cast Iron

Surface Finish < 0.5μm Ra (20μ")

Friction Material Data

FRICTION COEFFICIENT (WET)

Static 0.13 – 0.16

Dynamic 0.11 – 0.14

RECOMMENDED LOAD

Max Dynamic Pressure 3.2 N/mm2 (464 lbf/in2)

Max Rubbing Speed 45 m/s (130 ft/sec)

Max Specific Power 4.0 W/mm2 (3.4 HP/in2)

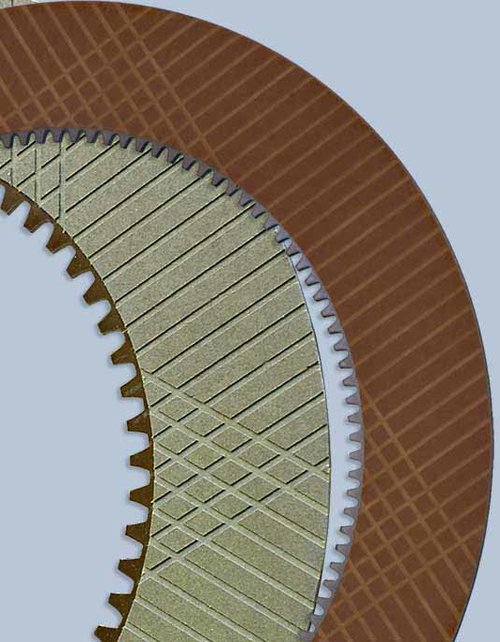

OIL GROOVING

- Multi-pass tangential groove patterns in variety of configurations

- Grooves can either be pressed or machined

DIMENSIONS

Friction Thickness 1.5 mm (0.060″) max / 0.40 mm (0.016″) min

Friction Diameter 1,000 mm (39″) max / 50 mm (2″) min

The above test data is provided for informational purposes and represents standards in controlled laboratory settings. Actual performance will vary by application and operating conditions.