Thermofiber 1479

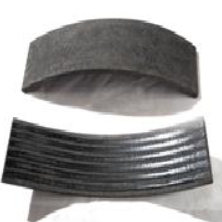

THERMOFIBER 1479 is ProTec’s upgraded flexible molded, metallic libonding segment, providing stable GG level friction and excellent machinability.

THERMOFIBER 1479’s HI-TENSILE characteristics provide a tough yet pliable material with superior rivet-hole strength.. It has good resistance to both fade and wear over a wide range of temperatures and is particularly effective in overcoming braking problems like squeal, shudder and grab.

THERMOFIBER 1479 comes in most industrial and drum passenger car sizes.

AVAILABLE FORMS Bonding Segments, Roll Lining

TF1479 Technical Data

COLOR Grey

STRUCTURE Flexible

COMPOSITION

Metallic Yes

Aramid Yes (Trace)

MAIN FIBER Glass

TYPE OF SERVICE Dry

COEFFICIENT OF FRICTION (μ)

Normal 0.47

Dynamic 0.48

WEAR RATE Very Good

SHEAR IMPACT STRENGTH 12MN/N2 @ 77 F

HARDNESS 75-80

SPECIFIC GRAVITY 2.00-2.15

MAX. RUBBING SPEED 25 m/s

MAX. DRUM TEMPERATURE 650 F

MAX. PRESSURE 180 psi

The above test data is provided for informational purposes and represents standards in controlled laboratory settings. Actual performance will vary by application and operating conditions.